Mike Brown has raced at the highest level of motocross, Supercross and off-road for factory-level teams during a career that has spanned over three decades. The 47-year-old racer is no longer competing to put food on the table, but is now doing selected events for Yamaha, FXR and Rockstar Energy just for fun. We talked “Brownie” into signing up for the last Wiseco Two-Stroke World Championship at Glen Helen Raceway with the promise of good times and a fun bike to race.

BUILDING BLUE

The Yamaha YZ250 two-stroke platform hasn’t changed very much in the last decade and a half, so finding parts for the build was not a problem. Brown told us in the very beginning that he would prefer a bike that produced usable power rather than explosive power. So, this became the foundation for our build. Our 2019 Yamaha YZ250 test unit was sitting at the Dirt Bike headquarters just begging to be raced, so work began immediately. The bike basically being brand new saved us a lot of time.

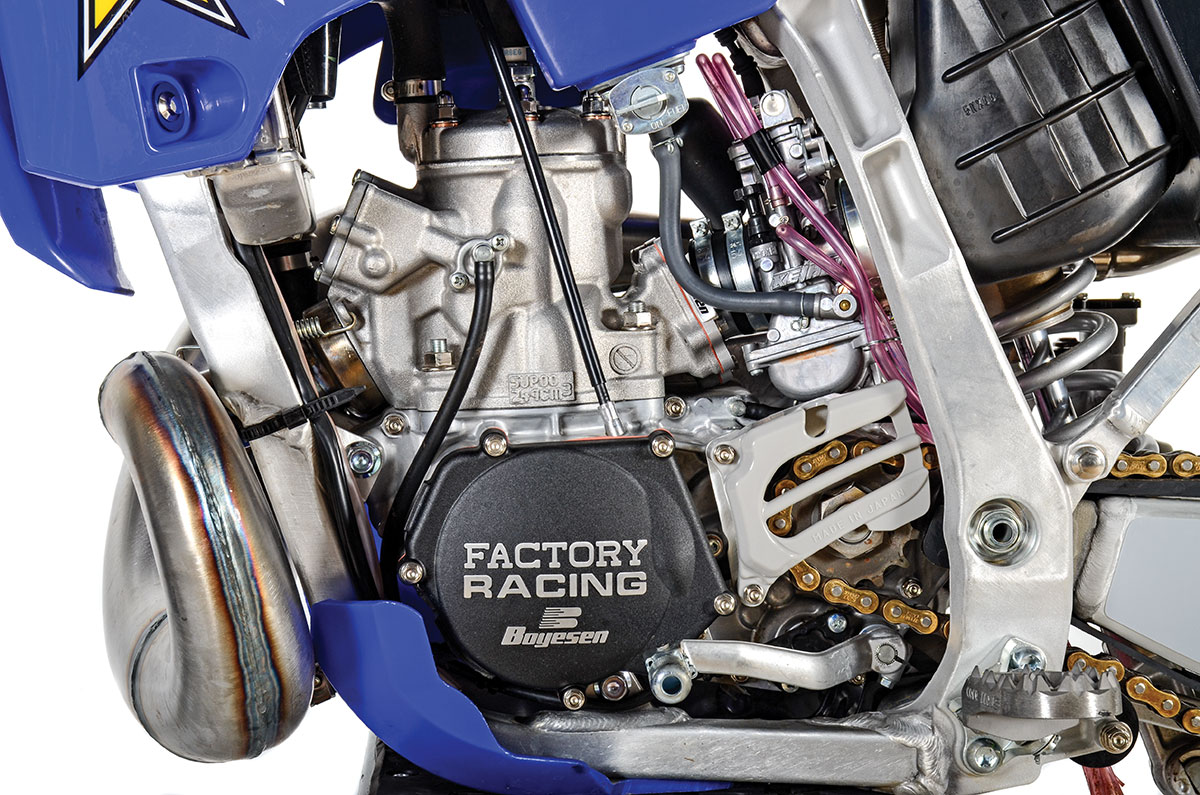

The engine wasn’t drastically changed internally. We did install a Rekluse Core Manual TorqDrive clutch and CNC-machined billet-aluminum clutch cover. The TorqDrive system is designed to provide the ability to fine-tune the transfer of power to the ground. Rekluse does this by using more disks in the same amount of space, so up to four additional friction disks are allowed to be used compared to the OEM unit. More friction plates means more torque capacity translating into more power transferred directly to the rear wheel. To further fine- tune power delivery, Rekluse offers a variety of different spring options that can be combined for a completely custom feel, depending on the rider’s preferences. The stiffer the spring setup is, the more torque is transferred to the rear wheel, but that makes the clutch pull harder as well. We settled on a slightly stiffer-than-stock clutch pull that allowed more torque transfer.

Another internal engine modification included the installation of a Boyesen Supercooler to replace the OEM water pump impeller with a larger one and a housing designed to flow fluids more efficiently to keep the engine running cooler. Those were the only internal engine modifications, but we did bolt on some mods as well. The OEM reed cage was replaced with a complete Rad valve system from Boyesen that utilizes multistage reed timing and aerodynamic surface optimization to improve performance. We also installed a complete FMF Factory Fatty pipe and a brand-new Titanium Powercore 2.1 silencer designed to improve performance throughout the power curve.

The chassis received ample amounts of attention in the way of aftermarket bolt-on items. Almost all the OEM nuts and bolts were replaced with Nickel Würks units, adding some bling and increased strength. Stock aluminum washers were also replaced with drilled and anodized parts. Brownie prefers a lower bar bend than what comes on the YZ250 stock, so the bars were replaced with Pro Taper EVO Husqvarna-bend handlebars, along with race-cut half-waffle grips. Wheels always take a beating, and the crew at Dubya made sure our YZ250 had top-of-the-line components. The stock units were replaced with Talon carbon fiber hubs, stainless steel spokes, aluminum nipples and black Excel A-60 rims. The last major chassis upgrade was done by Enzo Racing. The stock Yamaha Kayaba suspension components are among some of the best on the market today, but because we were building this machine to be raced by a fast guy (a slightly older fast guy but still a fast guy), it needed to be firmed up. Enzo Racing has been intertwined with factory KYB for years on the racing and development side, and Brownie worked with them back in his Yamaha of Troy days, so it was an easy fit.

DELIVERING RESULTS

So, with the bike built and a full day of testing with Brownie on the finished product behind us, it was time to race. Based strictly on race results, this Yamaha YZ250 is one of the best machines we have ever built. At 47 years of age, Brown was by far the oldest competitor on the Open Pro line, and he battled up front in both motos like a 20-year-old rookie hungry for a win. He would eventually finish just off the podium in fourth overall for the weekend. Considering that all the riders who finished in front of him were literally half his age, we were impressed. Fortunately, we don’t go strictly off race results, so we had to ride Brownie’s race machine for ourselves. Let’s just say it’s not going to see any major changes for a long time to come. The Enzo Racing suspension is a bit stiff initially but has a very progressive feel throughout the stroke, so the faster you go, the better it works. Power delivery mirrors the stock characteristics, but there is just more everywhere. And, it’s all easy to tap into, no matter where you are in the power curve. We do recommend running a 50/50 mix of VP Racing C-12 and 91-octane pump gas just to guard against detonation. The layout of Brownie’s bike is also comfortable, with everything in a neutral position and functioning properly. The steering head is tightened down significantly compared to stock, but that keeps the front end under control on the high-speed downhills and Talladega front straight at Glen Helen. This machine is a blast to ride, and there is no way Brownie is getting it back any time soon

Comments are closed.