Our KX500 build with Wayne Ransom is the focus on this weeks Two-Stroke Tuesday brought to you by Boyesen. The builder himself will update everyone on his progress and give professional insight on the direction of the build. There is tons of information in this post and be prepared it’s long! This weeks 2-Stroke Hardware section has KX500 items from Wiseco and Boyesen. Staying with the KX500 theme we look back at Destry Abbott’s KXZILLA in 2-Stroke Theater. If you missed the first two Ransom KX500 build updates don’t worry there are exclusive links at the bottom of this post! GET CAUGHT UP NOW.

“2016-17 Titanium kx450f fuel tank progress. The top and bottom are fit together and tacked. I just have to fab the rear piece and 2 rad shroud mounts.”

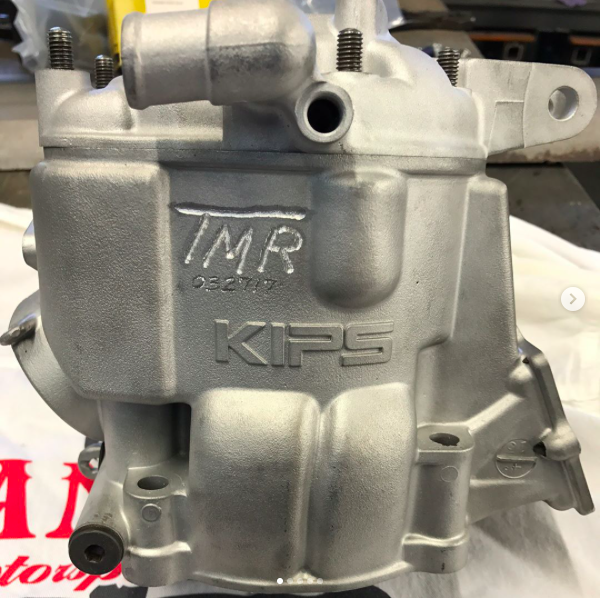

“Who wants to go fast??? Horsepower is not the main focus with this build, ridability is. That being said, we’ll still see over 60 hp at the wheel. Sponsor, Tom Morgan Racing, did an amazing job. I can not wait to rip the throttle back on this 500cc 2💨 swipe to see TMR’s craftsmanship. Thanks to millenniumtechnologies for kicking in the fresh cylinder plating!”

“Sweet kick starter came in the mail today.. Do you like it? On a serious note, my intent with making this kick starter is not only to make one that flows with the style of the frame and provide ample room for my expansion chamber, but more importantly, to show you guys that you don’t need a whole lot of sophisticated equipment to make something sweet. All it takes is a little thought, patience, and elbow grease. This kicker is starting out as a 6061 billet measuring 4″x12″x 1.5″ thick. I’ll use my old bridge port to bore the hole for the kicker boss and drill/tap the hole for the check ball. Then I’ll lay out my pattern and bandsaw cut it. Finally, I shape it with mostly hand files and block sand it clean.”

“Okay here’s the finished hand-sculpted kx500 kick starter. I added to the boss pivot to prevent the kicker from getting sloppy from wear. I used a dremel to sign it and to cut the grooves for boot contact area. I could have put it on the mill and ball milled these slots in, but I decided add some character only human hand can produce.”

“Basket case, is an accurate label for this kx500 motor that a friend gave to me. This is how the whole project started. You can see if your scroll down to some of my early posts. The back story: my friend was commissioned by one of his customers to rebuild the engine after the rod bearing failed. But the customer didn’t have the money to fix it. So the motor sat in a box like this for 2 years before I began asking my network to find me a kx500 motor for a project I wanted to do. So the engine was forfeited and gifted to me. Today, I have the task of going through the box and determining what parts are here, which ones are missing, and which ones need replacing. At first glance, the counter shaft is a definite as the sprocket grooved out the splines as was allowing the chain the rub the cases.. very common.”

“Experimenting today with some pipe ideas. I originally thought to do a titanium cone pipe.. but now I’m leaning towards hand hammering a Titanium pipe that will be seamless. The reason being is it takes way more skill to hammer out a tapered, curved pipe while keeping it to spec vs cutting, patterning, rolling and welding rings. I have a street bike build I will be making a titanium body for, so this pipe will push and tighten my skill set in forming Ti for my upcoming build. This design will be one smooth flowing line and offer crazy color and style. Not even factory pipes are seamless. I don’t know that it’s ever been done in this application?? First I laid out my pattern and quickly shaped up an aluminum shell just to see if I had the tooling to make it happen. Then, I tested my process on some Titanium scrap. And then I did some quick rough metal finishing so I could color it and see what the effect would look like.”

“Somethings not quite right here 🤔. Maybe I should have read the instructions.. So here’s the run down on using 2 right hand side radiators for our KX500AF build… At first I was going to cut the side plates out and install new ones, but upon further inspection I was pleased to see mylersradiator actually has the core fused to the outside plates. This allows more cooling because it allows the heat to soak into the side plates more efficiently, and makes for a stronger radiator as well. Most aftermarket rads (to my knowledge) do not do this. So with that being said, I decided to laminate the new mounts on top of the existing radiator side plates. An 1/8″ of added width in this section will be unnoticed. I also had to remove the factory frame mounts and add new.. slide for more. Next I will remake the tanks to fit this application.”

“I finished up the top radiator tanks for the Kx500af. Not my cleanest welds, but they should be leak free. I will finish the lowers once I hammer out the Titanium pipe. Then I’ll pressure test them to check for potential leaks.”

“Slight change of plans in this Titanium kx500af exhaust. I was going to bend the head tube in one shot. By my calculations, I knew it was going to be tight with the material getting too thin on the outside radius of the bend. And it turns out it was. It would work just fine for the application but ding and dent resistance would be way down. So for the sake of strength and durability I’ve decided to pie cut the head tube to retain its structural integrity. However, I will still be hammering out the cones.”

“Titanium kx500af headtube welded up and fully purged with full weld penetration. I colored the tube before I welded it to give some more visual effect. Welding is something I love but don’t get to do nearly enough.”

Just to give you an idea here it what the outside looks like.

“Taking a break from my work today to put work into this Titanium pipe for our kx500af build. To ensure the cones are concentric I use a contour gauge a specific points along the pipe. Because the radius is constantly changing from the cone taper, I take measurements at strategic segments along the length of each cone. The segments in between is where the art form comes into play as I will blend in those areas by eye creating a smooth transition. Here’s the first cone half roughed in.”

2-STROKE HARDWARE:

Wiseco Pro Lite Piston Kit Kawasaki KX500

Extreme racing conditions demand the strength and toughness that only forged pistons can offer and Wiseco leads the performance aftermarket by producing the highest quality forged pistons available. Each Wiseco Pro Lite Piston is built from race proven designs that are chosen by top race teams in all forms of racing including Supercross, Motocross and GNCC.

Extreme racing conditions demand the strength and toughness that only forged pistons can offer and Wiseco leads the performance aftermarket by producing the highest quality forged pistons available. Each Wiseco Pro Lite Piston is built from race proven designs that are chosen by top race teams in all forms of racing including Supercross, Motocross and GNCC.

Features:

- Extra lightweight piston design for instant throttle response

- Computer engineered piston skirt profile provides minimal cylinder wall friction

- Anti-detonation grooves and ring land diameter eliminate ring blow-by while maximizing performance

- Superior strength to weight ratio utilizing aerospace alloy construction

- Tired, tested and chosen by top race teams in all forms of racing

- Consistently true and durable forged piston design

- Provides extended life and sustained power

- Includes all gaskets and clips necessary for a top end rebuild

- Premium top end needle bearing

- High quality alloy pin

- High-performance ring set

Contact : www.wiseco.com

Boyesen Rad Valve

Patented, one piece, cast aluminum Reed Block system that delivers guaranteed bolt on performance. Carb boot, Carb boot clamp and gasket provided. No modifications required.

- Boyesen’s hot Rad valves provide plenty of offroad torque

- Custom reed cage holds Boyesen’s carbon fiber reeds

- Sustains flow velocity through the valve and redirects intake charge for balanced distribution to intake ports

- Quickens throttle response and ramps up horsepower throughout RPM range

- Solid one piece aluminum casting; bolts in easily

Contact: http: www.boyesen.com

2-STROKE THEATER:

See our Wayne Ransom KX500 build from the start! CLICK THE IMAGES BELOW NOW.

Click the image above to see the first major fabrications on the build.

Click the image above to see the titanium subframe take shape and hear about the titanium tank.

Comments are closed.